Fast and Flexible: Unpacking the Top Applications of Rapid Injection Molding

In the fast-paced world of manufacturing, the demand for quick turnaround times and flexible production processes has never been higher. Rapid injection molding has emerged as a vital solution, allowing businesses to efficiently produce high-quality plastic components. This innovative process combines speed with precision, enabling manufacturers to create complex designs with reduced lead times while keeping costs manageable. As industries continue to evolve, understanding the main applications of rapid injection molding becomes essential for those looking to stay competitive.

From prototyping to low-volume production, rapid injection molding offers a breadth of applications that cater to various sectors, including automotive, consumer electronics, and medical devices. These applications not only highlight the versatility of rapid injection molding but also demonstrate its capacity to meet the unique demands of different markets. By unpacking these top applications, we can better appreciate how this technology revolutionizes manufacturing processes and drives innovation across diverse fields.

Understanding Rapid Injection Molding

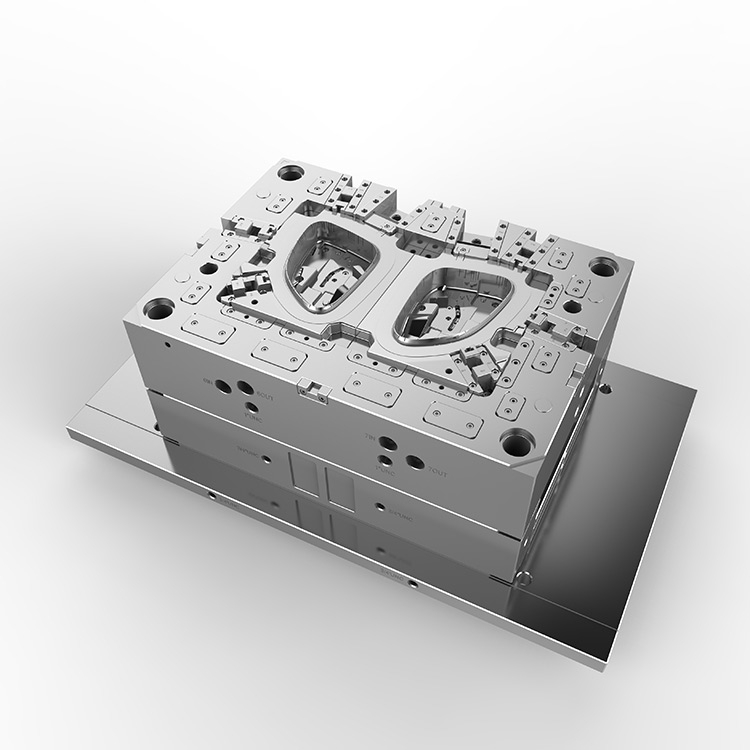

Rapid injection molding is an advanced manufacturing process designed to produce plastic parts quickly and efficiently. Unlike traditional injection molding, which can involve long lead times and high costs for tooling, rapid injection molding utilizes expedited methods and materials to create molds in a fraction of the time. This process is particularly beneficial for projects with strict deadlines or for industries where speed to market is crucial.

One of the key advantages of rapid injection molding is its flexibility in design and production. This process allows for quick adjustments and iterations on mold designs, making it ideal for prototyping and small batch production. Manufacturers can easily test and modify designs based on real-time feedback, which significantly shortens the development cycle compared to conventional methods. As a result, businesses can adapt more readily to market changes and customer demands.

In addition to its speed and adaptability, rapid injection molding often results in lower costs for small-to-medium production runs. The ability to use simpler molds and less expensive materials means that companies can produce high-quality parts without the significant upfront investment usually associated with traditional injection molding. This cost-effectiveness, combined with its rapid turnaround, makes rapid injection molding a preferred choice for various applications across multiple industries.

Key Applications in Various Industries

Rapid injection molding is revolutionizing product development across several sectors by providing speedy and cost-effective solutions for prototypes and low-volume production. In the automotive industry, manufacturers utilize rapid injection molding to create complex components and fittings that can be tested for fit and performance quickly. This technology allows for the rapid iteration of designs, ultimately leading to shorter development cycles and faster time to market.

In the medical field, the need for precision and compliance with regulatory standards makes rapid injection molding particularly valuable. Medical device companies rely on this process to produce highly accurate prototypes as well as low-volume production runs for devices and components like housings, connectors, and drug delivery systems. This ability to produce intricate and reliable parts without lengthy wait times is critical to fostering innovation in healthcare solutions.

The consumer products industry also benefits significantly from rapid injection molding. Brands often aim for quick market entry with new products, and rapid injection molding allows for the efficient production of functional prototypes and final products. From kitchen gadgets to electronic enclosures, the flexibility of this technology enables designers to make rapid adjustments, test user interactions, and deliver products that align closely with consumer expectations while maintaining cost-effectiveness.

Advantages Over Traditional Methods

Rapid injection molding offers significant time savings compared to traditional manufacturing processes. With improved design capabilities and the ability to produce prototypes quickly, businesses can move from concept to production in a fraction of the time. This expedited timeline allows for faster product launches, giving companies a competitive edge in rapidly changing markets.

Cost efficiency is another critical advantage of rapid injection molding. While traditional methods often involve high initial costs for tooling and setup, rapid injection molding allows for lower upfront investments. It enables businesses to produce smaller quantities economically, making it an attractive option for startups and those looking to test new products without incurring large expenses.

Flexibility stands out as a key benefit of rapid injection molding. The ability to easily modify designs and adapt to changing specifications makes it suitable for a range of industries. Whether it's for creating complex geometries or adjusting to new market demands, rapid injection molding provides the responsiveness that traditional methods often lack, ultimately enhancing innovation and product development capabilities.